Texaco Gas Stations Save Over 15% on Energy Bills With No Up-Front Costs

Gas stations with attached convenience stores are among the most energy-intensive commercial establishments globally, ranking second only to fast food restaurants in terms of energy consumption.

The reasons behind this high energy profile include long operating hours, substantial refrigeration needs, a high volume of customers, and the essential requirement for continuous air conditioning. These factors offer a wide array of opportunities to address and optimize energy efficiency.

In this particular project, the plan was to enhance the energy efficiency of the first store in a chain of five, aiming to establish a definitive proof of concept.

What are the project headlines?

The work carried out by the team on the test store yielded compelling results, justifying its implementation across the remaining locations. Here are the key outcomes:

Consistent 15% Energy Savings: An average energy savings of 15% was achieved.

Substantial Cost Savings: Over the course of a five-year contract, the project resulted in savings of £116,000 USD.

Significant Air Conditioning Savings: A remarkable 40.23% reduction in energy consumption was achieved for a single air conditioning unit.

Cost-Effective Pay-As-You-Save Model: The project was executed under a Pay-As-You-Save model, eliminating the need for upfront costs.

Enhanced Energy Visibility: Enescope provided total energy visibility at the site, down to the asset level, enabling the identification of areas of waste.

As a direct consequence of these impressive outcomes, the client has decided to expand the solution to the remaining four locations. Furthermore, they are contemplating implementing a similar approach for a portfolio of 10 supermarkets that they also own.

A Closer Look

Where did some of these energy savings actually come from?

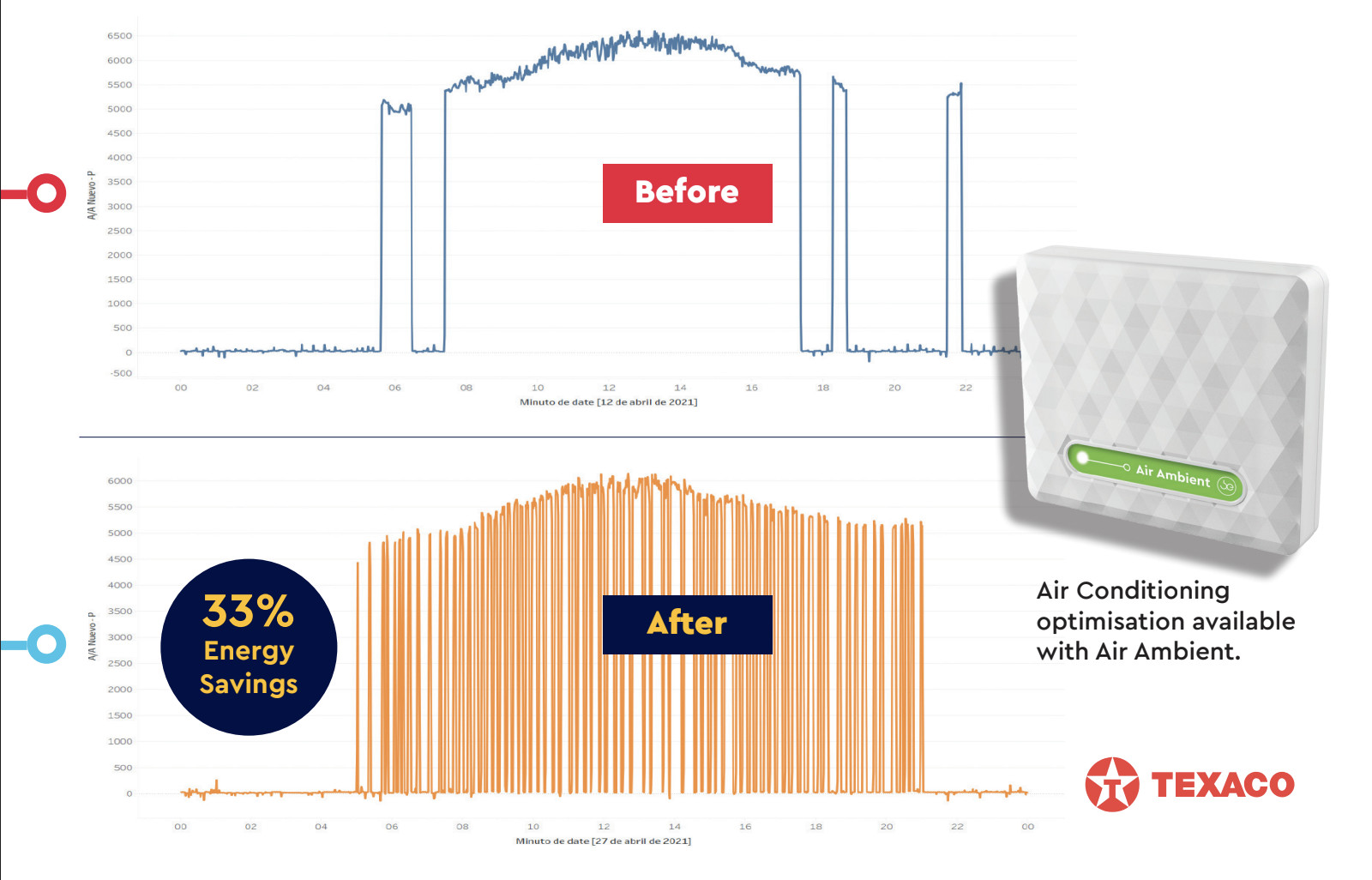

Take a look at the AC unit below:

The 'before' graph shows a unit operating almost constantly throughout the day. The 'after' graph demonstrates how using Best.Energy technology achieved a 33% energy savings by ensuring the proper cycling of the compressor.

On just this one unit, that equates to $1,565 energy cost savings per year.

What does the client think?

We asked Eduardo Bueso, Operations Manager at Texaco Service Stations, for his thoughts on the project:

"This project has given us the ability to understand and control our energy consumption in a completely different way, providing us with a transparent view of the operation where we can make investment decisions that are in line with real results. In just two months, we achieved significant energy savings; it has been a very enriching experience with operational and economic benefits for our group."